Sustainable Aviation Fuel: A Flight Toward a Greener Sky

In the ever-evolving world of aviation, a beacon of hope has emerged—Sustainable Aviation Fuel (SAF). This biofuel, akin to conventional jet fuel but with a significantly smaller carbon footprint, is becoming the lifeline for a more environmentally conscious aviation industry.

The Green Promise of SAF

SAF, derived from diverse feedstocks and cutting-edge technologies, has the power to dramatically reduce greenhouse gas (GHG) emissions throughout its life cycle. In some exciting developments, certain SAF pathways even boast a net-negative GHG footprint, marking a revolutionary step towards a sustainable future.

The significance of SAF extends beyond the clouds, addressing the crucial issue of aviation GHGs. According to the U.S. Environmental Protection Agency, these emissions contribute to 9%–12% of total transportation GHG emissions in the United States. SAF's lower carbon intensity positions it as a pivotal solution in the quest to shrink aviation's environmental impact.

A Bounty of Sustainable Feedstocks

Fueling the promise of SAF is a menu of sustainable feedstocks, an ecological buffet that can be harnessed responsibly. In the United States alone, an estimated 1 billion dry tons of biomass can be collected annually, offering a robust foundation for producing 50–60 billion gallons of low-carbon biofuels.

The diverse array of resources includes familiar faces like corn grain and oil seeds, alongside more unconventional yet equally potent sources like algae, fats, oils, greases, agricultural residues, forestry residues, wood mill waste, municipal solid waste streams, and even wet wastes such as manures and wastewater treatment sludge. Dedicated energy crops add to this rich tapestry of sustainable options.

This vast resource pool not only aligns with the projected fuel demand of the U.S. aviation industry but also opens avenues for additional volumes of drop-in low-carbon fuels. Moreover, it contributes to the creation of high-value bioproducts and renewable chemicals, further amplifying the positive impact of SAF on our ecological landscape.

As we look towards the future, where the sky is bluer, and our carbon footprint lighter, Sustainable Aviation Fuel emerges as a beacon of hope. It is not merely a fuel but a promise—a promise to soar higher with responsibility, ensuring that the wings of progress leave behind a greener trail for generations to come. The journey has begun, and with SAF leading the way, the flight towards a more sustainable aviation industry is well underway.

Navigating the Skies of Sustainability: Unveiling the Production Journey of Sustainable Aviation Fuel (SAF)

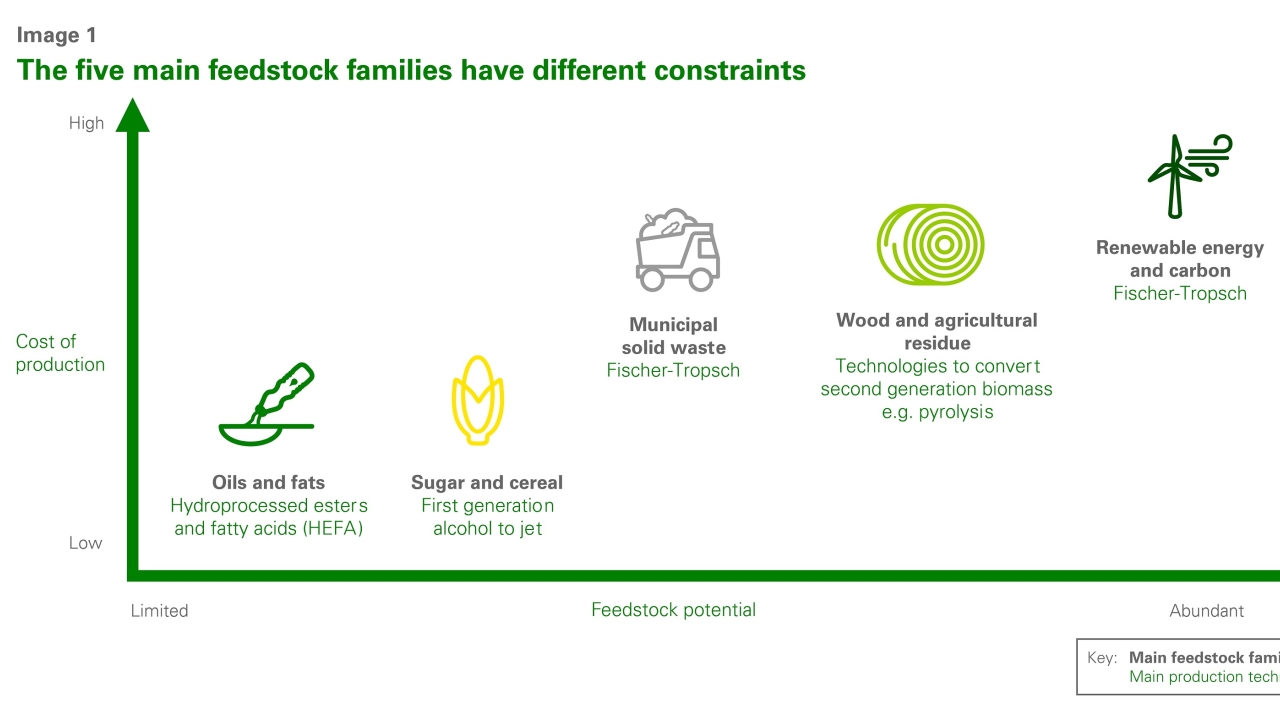

In the pursuit of a greener aviation future, the journey begins with the raw materials that form the bedrock of Sustainable Aviation Fuel (SAF) production. There are five primary families of these raw materials, each playing a crucial role in reshaping the aviation industry's impact on the environment: oils and fats, sugar and cereal, municipal solid waste, wood and agricultural residue, and renewable energy with carbon replacing a portion of the crude oil feedstock.

The production process of SAF is as diverse as its feedstocks, involving specific technologies tailored to each family. Before any technology hits the commercial runway, it must first receive the nod of approval from the fuel standard body ASTM, ensuring adherence to stringent quality and environmental standards.

There exist two distinct methods for producing SAF—standalone units and co-processing—each with its unique approach to sustainable aviation transformation. Standalone units take sustainable feedstocks and transform them into synthetic kerosene (SK). This SK, certified to the relevant annex in ASTM D7566 standard, is then blended with conventional jet fuel, culminating in the creation of SAF. The blend can reach up to 50%, meeting the rigorous specifications of ASTM D1655 or Defence Standard 91-091, and is supplied as conventional Jet A/ Jet A-1 fuel.

On the other hand, co-processing introduces a collaborative dance between sustainable and fossil feedstocks. In this intricate ballet, up to 5% sustainable feedstocks undergo hydro-processing alongside fossil counterparts in the refinery, forging a harmonious blend that embodies the essence of sustainable aviation.

The table of approved technology pathways and associated feedstocks serves as a roadmap, guiding the production journey from raw materials to certified SAF. Each pathway, a testament to innovation, marks a step forward in the aviation industry's commitment to reducing its environmental impact.

As the aviation industry steers towards a future where sustainability is paramount, the intricate process of SAF production becomes a crucial piece of the puzzle. It is a testament to the collaborative efforts, technological advancements, and commitment to cleaner skies. With each drop of certified SAF blended into conventional jet fuel, the aircraft of progress takes off, leaving a trail of environmental responsibility across the skies. The journey towards sustainable aviation is well underway, with SAF leading the way into a future where the skies are not just destinations but sanctuaries of ecological harmony.

No comments:

Post a Comment